Study of Contamination & Restorative Sciences

Ionic Contamination & IPC Electronic Assembly Cleanliness Limits

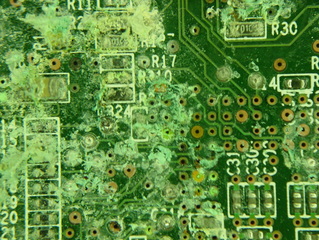

The IPC Industry Association and its collection of electronic assembly standards are employed by Coastal Technical Services to assess circuit board / assembly cleanliness. The IPC/ EIA consortium is widely accepted in the electronics industry, with some of the cleanliness specification work rooted in U.S. defense department research. Below are a few excerpts relating to residue limits.

Manufacturers are not limited to the stated levels of residue. Some circuit manufacturers follow more stringent guidelines. Likewise nonionic residues can lead to early failure in electronic assemblies, and may require other testing methods (eg. accelerated aging/ burn in). Coastal Technical Services regards the quantified levels of ionic contamination as guidelines, which incorporate the combined histories, experience, and wisdom of IPC members.

Ion Chromatography (per IPC-TM-650 "Test Methods Manual"): Ion chromatography is an accurate and cost effective analytical procedure employed by IPC member laboratories to quantify the amount of ionic material on an electronic assembly surface. The presence of ionic species on circuit assemblies can corrode and damage circuitry or disrupt electrical operation. This test method acknowledges a variety of anions and cations, (including weak organic acids), that are appropriate for residue analyses. Commonly monitored and controlled species include Bromide, Fluoride, Nitrate, Nitrite, Phosphate, Sulfate, Ammonium, Calcium, Lithium, Magnesium, Potassium, Sodium, etc. Many other ionic species are worthy candidates for testing. The equivalent charge carrying capacity of other species can be easily derived and correlated to a known species such as sodium and/or chloride (Na+ / Cl-).

There is a mistaken belief that chloride is the only species of interest when assessing contamination risk to electronic assemblies. While chloride certainly does have reactive chemical properties, many other ionic species can cause equivalent or worse damage. All ionic contaminants are capable of disrupting or damaging electronic circuitry. There are multiple attributes and mechanisms that contribute to an ion's ability to damage circuitry. Chemical reactivity is one factor. Electrical conductivity is another. Water attraction and absorption is another, as is solubility. Ionic mobility is yet one more consideration. Depending upon the ion(s) or chemical compounds involved, the potential risk and mechanism(s) for failure are quite diverse. Add electrical power to all of these conditions, and many modes of failure are possible. For these reasons it is essential to enlist the assistance of a qualified chemistry and electronics expert to analyze exposure and assess risk.

Tracking Ionic Contamination

Zinc & Metal Whiskers

Coastal Technical Services is actively involved in the study of the effects of Zinc and other metal whisker phenomena concerning electronic assemblies and printed circuits. Moreover, Coastal Technical Services has been instrumental in assisting original equipment manufactures in addressing field failure problems as well as developing remediation efforts associated with metal whisker exposure events.

What are Zinc Whiskers?Zinc whiskers are electrically conductive, crystalline structures of Zinc that sometimes grow from surfaces where Zinc is used as a final finish. Zinc whiskers have been observed to grow to lengths of several millimeters (mm) and in rare instances to lengths in excess of 10 mm. Numerous electronic system failures have been attributed to short circuits caused by Zinc whiskers that bridge closely-spaced circuit elements maintained at different electrical potentials.

Zinc is only one of several metals that is known to be capable of growing whiskers. Other metals that may form whiskers include some cadmium, indium, antimony, silver among, tin and tin alloys.

Differences between Whiskers and Dendrites

People sometimes confuse the term "whiskers" with a more familiar phenomenon known as "dendrites" commonly formed by electrochemical migration processes. Therefore, it is important to note here that whiskers and dendrites are two very different phenomena. A "Whisker" generally has the shape of a very thin, single filament or hair-like protrusion that emerges outward (z-axis) from a surface. "Dendrites", on the other hand, form in fern-like or snowflake-like patterns growing along a surface (x-y plane) rather than outward from it. The growth mechanism for dendrites is well-understood. While the precise mechanism for whisker formation remains unknown, it is known that whisker formation does not require either dissolution of the metal nor the presence of an electromagnetic field.

For more information concerning metal whisker phenomena visit the following NASA Government website:

http://nepp.nasa.gov/WHISKER/

Hydrogen Sulfide

Coastal Technical Services is involved in the study of the effects of Hydrogen Sulfide on electronic assemblies and printed circuits. Moreover, Coastal Technical Services has been actively assisting original equipment manufacturers in addressing field failure problems associated with Hydrogen Sulfide exposure.

Corrosion of Materials and Effects on Vegetation and Animal life

Hydrogen sulfide in the air may attack and corrode copper, silver, zinc, lead, aluminum, iron and other metals. The corrosive effect, evident as rust, black oxide, or tarnish, has been demonstrated on metals exposed to levels of 0.01 ppm for 30 days. Copper is a susceptible metal. Corrosion of copper is of special concern because of the prevalence and dependence on copper in electrical/ electronic equipment components. Increased moisture in the air increases corrosion. Some states have proposed lower standards for areas with higher relative humidities.

Potential Sources of Hydrogen Sulfide

Hydrogen sulfide is a colorless, flammable gas that is heavier than air. It is also called hydrosulfuric acid, stink damp and sewer gas. Hydrogen sulfide occurs naturally and can be found in volcanic gases, petroleum deposits, natural gas, and hot springs (ATSDR 1999). Hydrogen sulfide is formed when organic matter undergoes putrefaction. Hydrogen sulfide can be found in sewage treatment facilities, fish aquaculture and in areas where livestock or manure is handled (ATSDR 1999). Much of the public concern about confined animal feeding operations has centered on hydrogen sulfide emissions. Hydrogen sulfide is also present in emissions from industrial paper plants that use the Kraft Process. The leather industry uses hydrogen sulfide to remove hair from hides before tanning and tons of hydrogen sulfide have been used by facilities for the production of heavy water for nuclear reactors (Klaassen et al. 1996). Industrial sources of hydrogen sulfide also include petroleum refineries, natural gas plants, petrochemical plants, coke oven plants, and food processing plants (ATSDR 1999).

*Source: Literature Review of the Health Effects Associated with the Inhalation of Hydrogen Sulfide, Idaho Department of Environmental Quality Boise, Idaho, Prepared by: Pat McGavran, Ph.D D.A.B.T., June 19, 2001

The IPC Industry Association and its collection of electronic assembly standards are employed by Coastal Technical Services to assess circuit board / assembly cleanliness. The IPC/ EIA consortium is widely accepted in the electronics industry, with some of the cleanliness specification work rooted in U.S. defense department research. Below are a few excerpts relating to residue limits.

Manufacturers are not limited to the stated levels of residue. Some circuit manufacturers follow more stringent guidelines. Likewise nonionic residues can lead to early failure in electronic assemblies, and may require other testing methods (eg. accelerated aging/ burn in). Coastal Technical Services regards the quantified levels of ionic contamination as guidelines, which incorporate the combined histories, experience, and wisdom of IPC members.

Ion Chromatography (per IPC-TM-650 "Test Methods Manual"): Ion chromatography is an accurate and cost effective analytical procedure employed by IPC member laboratories to quantify the amount of ionic material on an electronic assembly surface. The presence of ionic species on circuit assemblies can corrode and damage circuitry or disrupt electrical operation. This test method acknowledges a variety of anions and cations, (including weak organic acids), that are appropriate for residue analyses. Commonly monitored and controlled species include Bromide, Fluoride, Nitrate, Nitrite, Phosphate, Sulfate, Ammonium, Calcium, Lithium, Magnesium, Potassium, Sodium, etc. Many other ionic species are worthy candidates for testing. The equivalent charge carrying capacity of other species can be easily derived and correlated to a known species such as sodium and/or chloride (Na+ / Cl-).

There is a mistaken belief that chloride is the only species of interest when assessing contamination risk to electronic assemblies. While chloride certainly does have reactive chemical properties, many other ionic species can cause equivalent or worse damage. All ionic contaminants are capable of disrupting or damaging electronic circuitry. There are multiple attributes and mechanisms that contribute to an ion's ability to damage circuitry. Chemical reactivity is one factor. Electrical conductivity is another. Water attraction and absorption is another, as is solubility. Ionic mobility is yet one more consideration. Depending upon the ion(s) or chemical compounds involved, the potential risk and mechanism(s) for failure are quite diverse. Add electrical power to all of these conditions, and many modes of failure are possible. For these reasons it is essential to enlist the assistance of a qualified chemistry and electronics expert to analyze exposure and assess risk.

Tracking Ionic Contamination

Zinc & Metal Whiskers

Coastal Technical Services is actively involved in the study of the effects of Zinc and other metal whisker phenomena concerning electronic assemblies and printed circuits. Moreover, Coastal Technical Services has been instrumental in assisting original equipment manufactures in addressing field failure problems as well as developing remediation efforts associated with metal whisker exposure events.

What are Zinc Whiskers?Zinc whiskers are electrically conductive, crystalline structures of Zinc that sometimes grow from surfaces where Zinc is used as a final finish. Zinc whiskers have been observed to grow to lengths of several millimeters (mm) and in rare instances to lengths in excess of 10 mm. Numerous electronic system failures have been attributed to short circuits caused by Zinc whiskers that bridge closely-spaced circuit elements maintained at different electrical potentials.

Zinc is only one of several metals that is known to be capable of growing whiskers. Other metals that may form whiskers include some cadmium, indium, antimony, silver among, tin and tin alloys.

Differences between Whiskers and Dendrites

People sometimes confuse the term "whiskers" with a more familiar phenomenon known as "dendrites" commonly formed by electrochemical migration processes. Therefore, it is important to note here that whiskers and dendrites are two very different phenomena. A "Whisker" generally has the shape of a very thin, single filament or hair-like protrusion that emerges outward (z-axis) from a surface. "Dendrites", on the other hand, form in fern-like or snowflake-like patterns growing along a surface (x-y plane) rather than outward from it. The growth mechanism for dendrites is well-understood. While the precise mechanism for whisker formation remains unknown, it is known that whisker formation does not require either dissolution of the metal nor the presence of an electromagnetic field.

For more information concerning metal whisker phenomena visit the following NASA Government website:

http://nepp.nasa.gov/WHISKER/

Hydrogen Sulfide

Coastal Technical Services is involved in the study of the effects of Hydrogen Sulfide on electronic assemblies and printed circuits. Moreover, Coastal Technical Services has been actively assisting original equipment manufacturers in addressing field failure problems associated with Hydrogen Sulfide exposure.

Corrosion of Materials and Effects on Vegetation and Animal life

Hydrogen sulfide in the air may attack and corrode copper, silver, zinc, lead, aluminum, iron and other metals. The corrosive effect, evident as rust, black oxide, or tarnish, has been demonstrated on metals exposed to levels of 0.01 ppm for 30 days. Copper is a susceptible metal. Corrosion of copper is of special concern because of the prevalence and dependence on copper in electrical/ electronic equipment components. Increased moisture in the air increases corrosion. Some states have proposed lower standards for areas with higher relative humidities.

Potential Sources of Hydrogen Sulfide

Hydrogen sulfide is a colorless, flammable gas that is heavier than air. It is also called hydrosulfuric acid, stink damp and sewer gas. Hydrogen sulfide occurs naturally and can be found in volcanic gases, petroleum deposits, natural gas, and hot springs (ATSDR 1999). Hydrogen sulfide is formed when organic matter undergoes putrefaction. Hydrogen sulfide can be found in sewage treatment facilities, fish aquaculture and in areas where livestock or manure is handled (ATSDR 1999). Much of the public concern about confined animal feeding operations has centered on hydrogen sulfide emissions. Hydrogen sulfide is also present in emissions from industrial paper plants that use the Kraft Process. The leather industry uses hydrogen sulfide to remove hair from hides before tanning and tons of hydrogen sulfide have been used by facilities for the production of heavy water for nuclear reactors (Klaassen et al. 1996). Industrial sources of hydrogen sulfide also include petroleum refineries, natural gas plants, petrochemical plants, coke oven plants, and food processing plants (ATSDR 1999).

*Source: Literature Review of the Health Effects Associated with the Inhalation of Hydrogen Sulfide, Idaho Department of Environmental Quality Boise, Idaho, Prepared by: Pat McGavran, Ph.D D.A.B.T., June 19, 2001